Digitaltest specializes in high-performance automated test systems (ATE) for electronic circuit boards, optimizing manufacturing through seamless integration of CAD, testing, and production. Their advanced in-circuit, functional, and flying probe testers ensure precision, reliability, and efficiency. With powerful production automation software and quality management solutions, they enhance productivity and reduce costs. Digitaltest also offers comprehensive testing services, providing full outsourcing solutions worldwide.

The Sparrow MTS 30 is a 19“ test system that can be integrated into any standard rack. The In-Circuit tester can also be used as benchtop test system. With this compact and flexible tester you can perform both analog and digital In-Circuit and functional tests.

Description

In spite of its small footprint the Sparrow features 9 slots for module cards with up to 1,152 test pins, which are available as analog or hybrid pins or even a combination of the two. In addition, the benchtop tester can accommodate up to four programmable power supplies. With the proven In-Circuit and functional test modules you can handle a majority of the possible test scenarios simply and economically.

The Sparrow offers maximum flexibility and test capability in a small footprint.

- Up to 1,152 pins

- 19 inch – easy integration into a standard rack

- Very small footprint

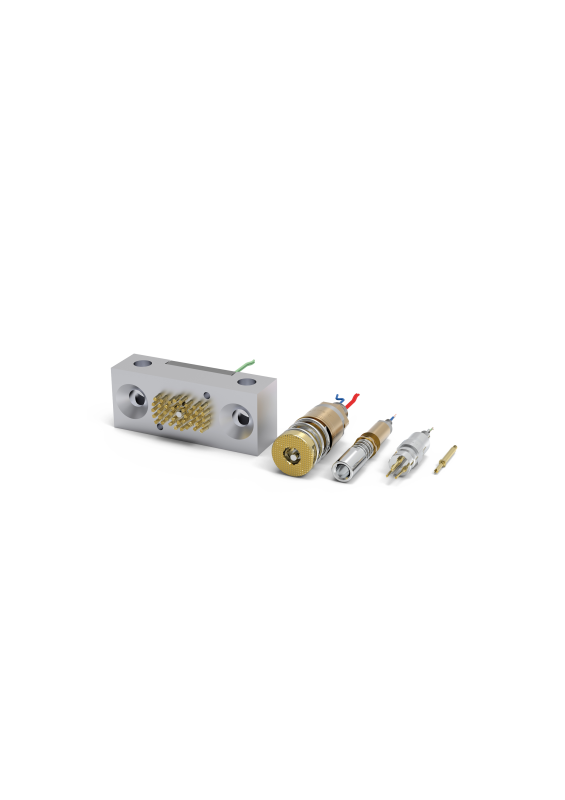

- Fast Access Interface (FAI) – quick exchange interface for easy maintenance

- Real parallel test: easy implemention of Lambda edition

- Maximum board size (mm) - Unlimited

- Interface - Cable

- System size - (LxWxD)483 x 178 x 5,700

- Format - 19" housing, flexible

- Possible versions - analog, hybrid & Lambda edition

Options

Fast Access Interface (FAI)

You can equip our Sparrow with a quick-change interface, the so-called Fast Access Interface (FAI). This gives you quick and simple access to the pin cards without cumbersome plugging and unplugging of the flat cables. You save time with maintenance, for example: simply fold the slot cover over to the side – either to the left or right – and remove the pin card.

External switch for vacuum adapter

The external vacuum switch allows you to control a vacuum adapter directly through the Sparrow. This is a box which is connected to the rear of the In-Circuit tester. Use the VacOn or VacOff commands to enable or disable the vacuum switch.

Functional test tower

Are you looking for a flexible system with standard interface for your functional test? You’re not alone. Which is why we also offer our 19“ Sparrow as a functional test tower with standardized pylon interface. In addition to the pins for In-Circuit testing and functional testing, this can also include blocks for high voltage/current, pneumatic terminals or glass fiber optics. The tower can be individually configured and can accommodate additional IEEE- or PXI-based functional test equipment.

Our engineers will be happy to design similar integrations on request and with the support of our integration specialist partners.

Power Supply Rack

If the four power supplies on the Sparrow are not enough, we offer a Power Supply Rack with twelve additional power supplies. Like the benchtop tester, this is for a 19“ rack and allows you to install additional UPC modules. Multiple panels, different voltages or parallel testing of more complex test objects are then no problem with our compact test system.

Parallel testing

Lambda edition: real parallel testing as the solution

Would you like to test multiple boards in parallel and save time? We have the solution: real parallel testing with the Lambda edition. With this technology you can test two or more assemblies at the same time, thereby optimizing the cycle times and shortening the test time or performing the tests using the shortest path. An ICT or functional test is performed by two or more independent test heads, reducing the test time by the corresponding factor. This applies to multi-panels as well as for multiple independent single test objects.

The Lambda edition thus reduces the test time for two objects for example by 50 percent, or 75 percent for four, and so on.

Advantages of parallel testing

- Optimizes cycle times

- Small, economical test heads

- Powerful, flexible software environment

- Assemblies can be tested without additional effort

- Low hardware costs

- Takes up less space

Learn more about our Lambda edition.

Add -Ons

- Boundary scan ICT

- CAN / LIN Modules

- IEEE, RS232, USB Modules

- PXI Devices

- Optical Test Modules